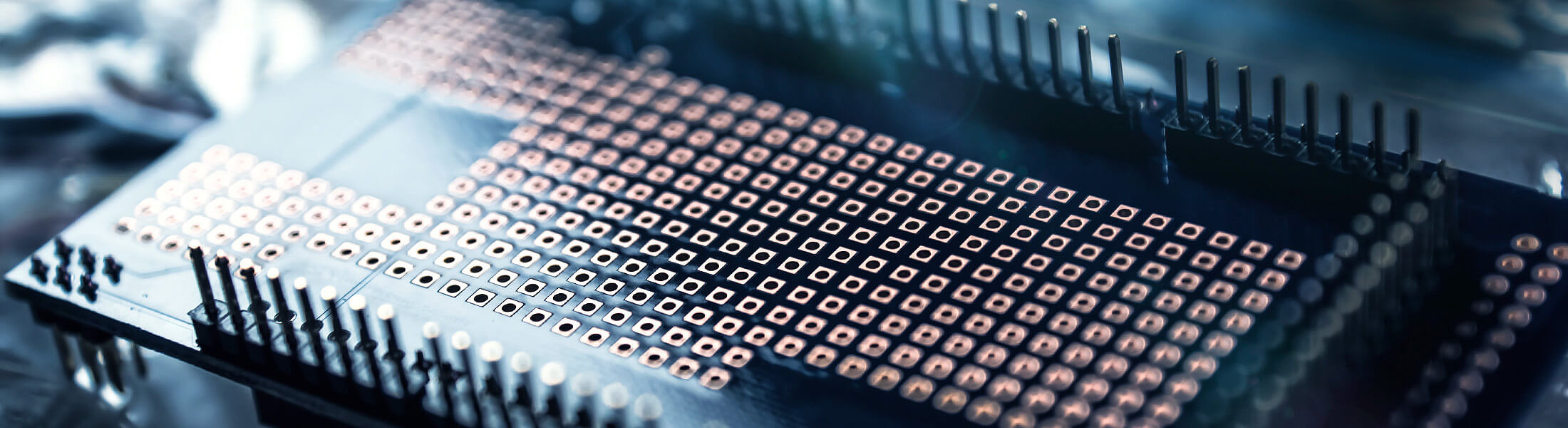

Wire solutions for the electronics industry

Expertise in materials, shapes, and surface coatings

High-quality electronic wire from bedra can be found worldwide in passive or electronic components. The trend towards miniaturization in electronic components is placing higher demands on material selection and processing technologies. With our decades of experience and strong research and development program, it is precisely here that we demonstrate our leadership in the market. Our extensive knowledge of materials and processing enables us to develop new solutions to meet each unique customer’s need.

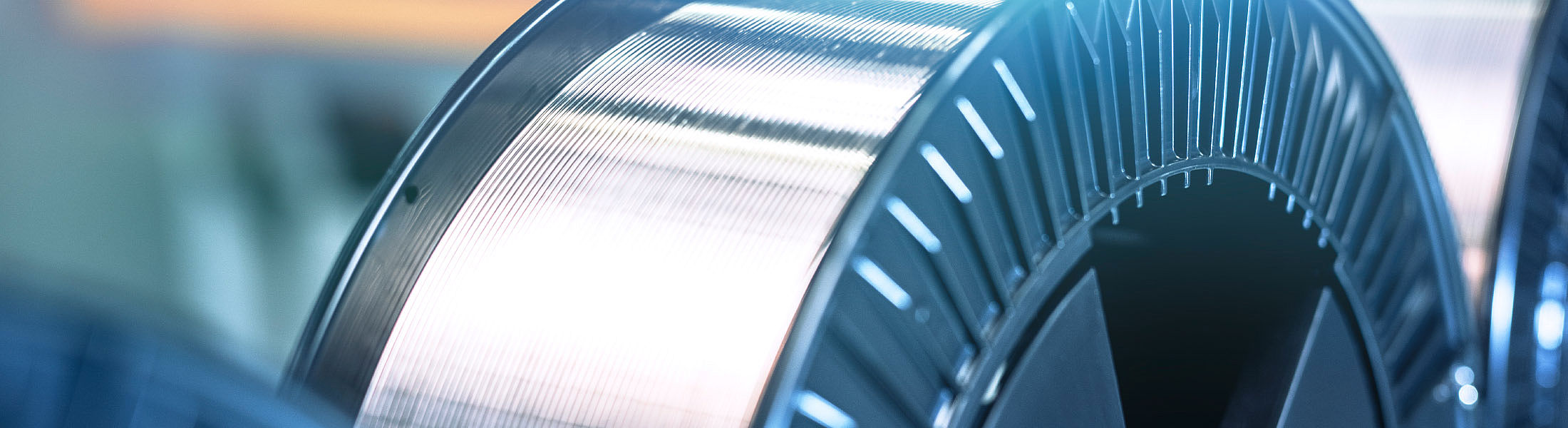

Increased demands in processing quality

Against this background, we are true specialists in the production of square, rectangular, and octagonal profiles, as well as flat and round wires in smooth, knurled, coated, and uncoated designs. We meet the tightest tolerances in dimension, diagonal and edge radius, as well as exact knurling, precision, and process stability. These are impressive proofs of our expertise. At the same time, it reflects the increased demands placed on state-of-the-art wire processing. Our fulfillment of optimum straightness requirements with customer-specific parameters and precise layer winding round out our self-imposed quality standards.

Modern surface finishing

To produce consistently high surface quality, we use different electroplating equipment and coating variants. Having our own laboratory enables us to design materials and process that meet our rigorous quality requirements at all times. Our surface coating capability ranges from pure tin coatings, through variants with nickel or copper barrier layers, to multi-layer technology. Using high-purity tin anodes ensures we meet the requirements for optimal solderability.

Our reflow technology keeps galvanized wires more free of whiskers. At the same time, it supports modern manufacturing processes in the application industry. The production process is rounded out by strictly following all environmental standards, along with an inspection of ROHS compliance by certified external testing labs.

Advantages of our electronic wire

A variety of wire geometries

bedra is the specialist in the production of square, rectangular, and octagonal profiles, flat and round wires in smooth and knurled design. Strict adherence to specifications for dimension, diagonal, and edge radius, as well as exact layer winding ensure that our customers’ high demands are met.

Many applications for bedra electronic wire

bedra electronic wires are used in the connector and bobbin industry. With our versatile alloy variants, we also offer product solutions for heating cables and special wires for the cable industry.

High-quality surface finishes

We apply functional layers to our electronic wires on our own electroplating equipment. This ranges from simple pure tin coatings, through variants with nickel or copper barrier layers, to multi-layer technology. Of course, compliance with the RoHS guideline is ensured both in alloy composition and in electroplating.

Highly precise knurling

Upon request, bedra electronic wires are available with a highly precise knurling or grooving. In doing so, compliance with the most stringent tolerances of the customer-specific product parameters is ensured.

Overview of our electronic wires

Tin-bronze alloys

Brass alloys

Nickel-silver alloys

Copper materials

Highly conductive alloys

Special alloys

Berkenhoff GmbH (headquarters)

- Kinzenbach plant

- Berkenhoffstrasse 14

- 35452 Heuchelheim

- Germany

- +49 641 601 0

- +49 641 601 222

- info(at)bedra.com

Berkenhoff GmbH

- Merkenbach plant

- Rehmühle 1

- 35745 Herborn

- Germany

- +49 2772 5002 0

- +49 2772 5002 155

- info(at)bedra.com