betterbrass ONE.9

The revolution for plain brass wires

bedra combines a better continuous casting process with better heat treatment methodologies to create an unparalleled new EDM wire: betterbrass ONE.9. Our engineers created a brass wire electrode comprised of a completely new alloy that delivers up to 10% faster cutting speed, plug-and-play on all machine types and many more. This EDM wire utilizes innovative and efficient production processes to deliver performance never before seen in a traditional brass wire.

- Extremely reliable performance

- Plug-and-Play on all machine types

- Cuts up to 10% faster than traditional brass wire

- Innovative alloy and casting technology delivers high process performance and reliability

- Specially developed heat treatment process enhances cutting performance

- Better performance at a better price

Faster eroding. Less wire consumption. Lower wire costs.

Further information can be found in the betterbrass flyer.

PDF DatasheetTechnical data

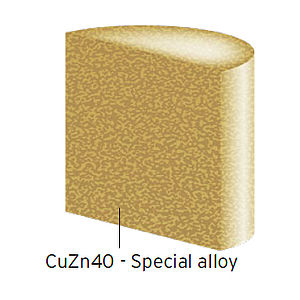

| Core | CuZn40 - special alloy |

| Surface | Paraffin-free |

| Tensile strength | 900 MPa / 130,000 PSI |

| Elongation | 1 % |

| Color | Pyrit-Gold |

| Diameter | 0.20 / 0.25 / 0.30 mm |

| Spool types | K160, K200, K250, K355, P5, P10, P15 |

Cross-section

Delivery program

Run-off-times wire electrodes

Further product information

Berkenhoff GmbH (headquarters)

- Kinzenbach plant

- Berkenhoffstrasse 14

- 35452 Heuchelheim

- Germany

- +49 641 601 0

- +49 641 601 222

- info(at)bedra.com

Berkenhoff GmbH

- Merkenbach plant

- Rehmühle 1

- 35745 Herborn

- Germany

- +49 2772 5002 0

- +49 2772 5002 155

- info(at)bedra.com