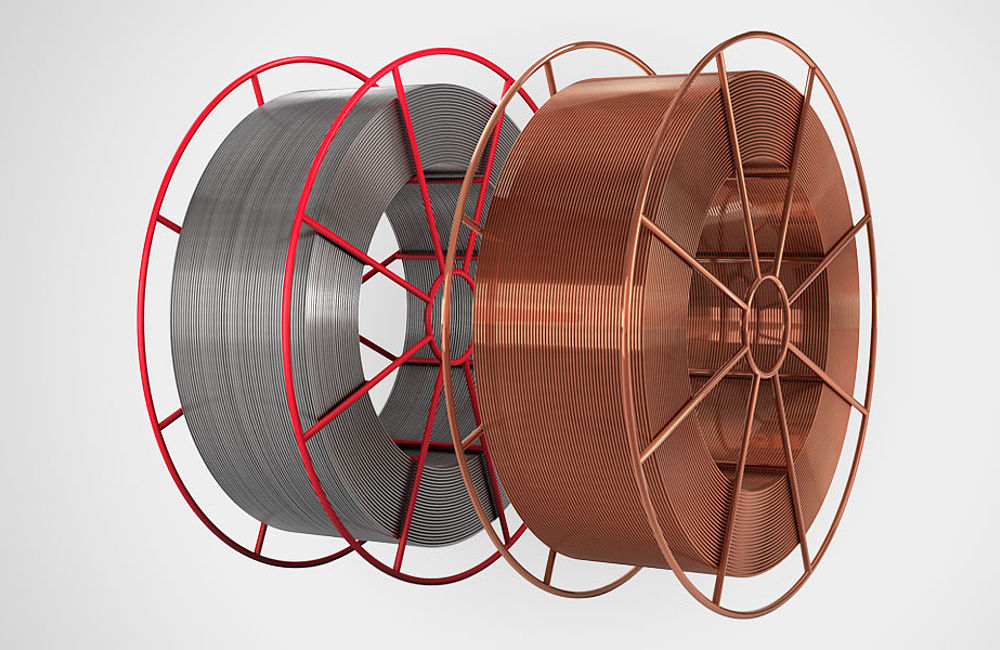

For more than 130 years we have been synonymous with innovative high-tech precision wires. From our plants in Heuchelheim and Herborn we serve the needs of our customers all over the world. We developed the bercoweld® series for brazing and welding copper and copper alloys. In 2021 we expanded our wire portfolio to include high-quality aluminium alloy filler metals. For this purpose, we have combined our experience of more than 130 years in wire production with the latest technologies and specialists from the aluminium sector. That‘s why we can now produce aluminium welding wires in well-known high bedra quality: berAlweld®

Our complex range of wire electrodes for brazing and welding provides the right product for every application.

Our range of wires for brazing and welding currently comprises more than 30 alloys of the following material groups:

- Low-alloy copper alloys

- Tin bronzes

- Aluminium bronzes

- Copper-nickel alloys

- Aluminium alloys

- Special alloys

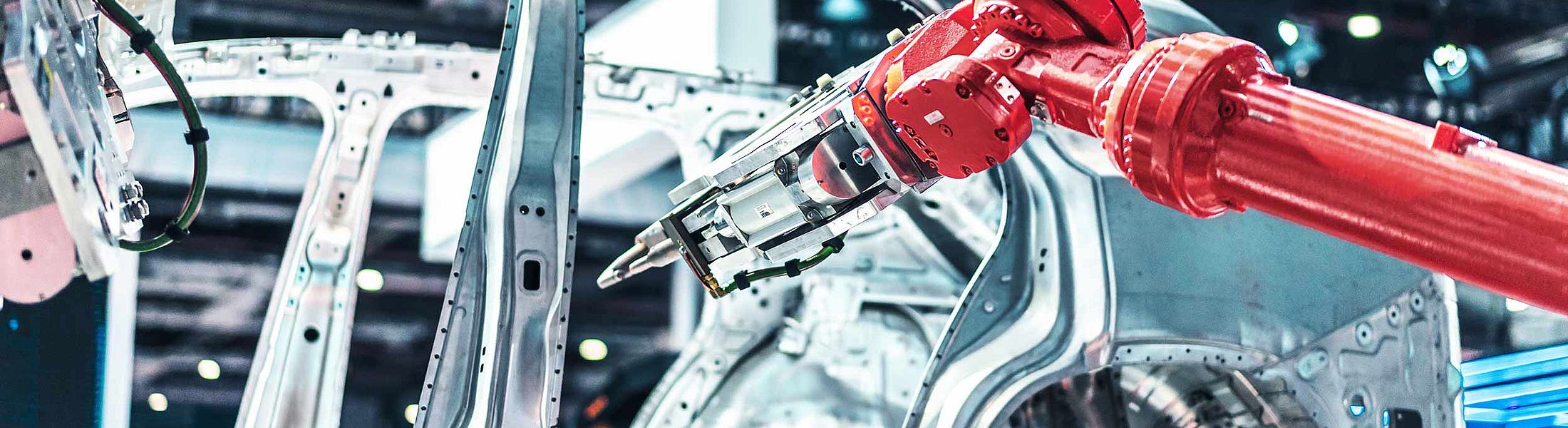

No matter whether you prefer MIG/MAG brazing or welding, TIG welding, laser and plasma brazing, or wire flame spraying: The bercoweld® and berAlweld® range is as diverse as your applications. This is one reason why renowned companies from the automotive industry, plant construction, and the offshore and onshore sectors rely on bercoweld® and berAlweld® as a fundamental component of an innovative joining technology.