gapstar® ONE.9

New generation of high performance EDM-wires with bedra TRIMPAC® technology

The new EDM high performance wire with the bedra TRIMPAC® technology. From the strengths of the wire generations cobracut®, broncocut® and topas® bedra developed the new coating technology TRIMPAC®.The result is gapstar® ONE EDM wire.

- The revolution in speed and precision

- Significant increase of feed rates in rough cut and trimcuts without adjustments

- Reduced abrasion of wire preserves wire guides and power contacts

- Novel TRIMPAC® coating enables roughness on the workpiece of Ra= 0.25 µm

- Reliable, automatic wire threading

- Unprecedented cutting performance for a wide range of applications

- Uncompromising precision and surface quality

- lncreased stiffness and excellent straightness for automatic threading

Further information can be found in the gapstar® ONE product video or in the gapstar® ONE brochure.

Download gapstar® ONE brochure

Technical data

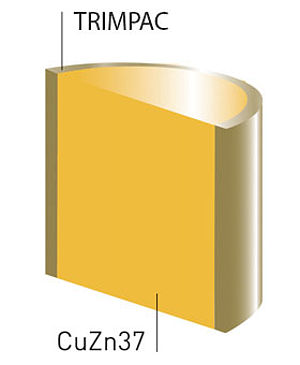

| Core | CuZn37 |

| Coating | TRIMPAC |

| Tensile strength | 900 MPa / 130,000 PSI |

| Elongation | >1% |

| Color | Amber brown |

Cross-section

Delivery program

Run-off-times wire electrodes

Further product information

Berkenhoff GmbH (headquarters)

- Kinzenbach plant

- Berkenhoffstrasse 14

- 35452 Heuchelheim

- Germany

- +49 641 601 0

- +49 641 601 222

- info(at)bedra.com

Berkenhoff GmbH

- Merkenbach plant

- Rehmühle 1

- 35745 Herborn

- Germany

- +49 2772 5002 0

- +49 2772 5002 155

- info(at)bedra.com