confreecut ONE

The innovative solution for contamination-free wire erosion

To increase efficiency in the EDM production of contamination-free components, bedra has developed the innovative confreecut ONE EDM wire. confreecut ONE stands for contamination-free and fast machining with low wire guide wear and lower wire costs. The wire has a high-purity outer nickel coating with an optimized layer thickness. Run lengths of up to 60,000 m per spool permit significantly more autonomous production compared with the usual fabrication of molybdenum and tungsten wires.

bedra was able to prove in numerous tests that confreecut ONE reduces the copper and zinc contamination, and zinc is reduced to almost zero during processing with 2-4 trim cuts. In the process, the components were examined for these residues using highly sensitive analysis technology. bedra will be happy to advise you on your specific erosion application.

Further information can be found in the confreecut ONE brochure:

Download confreecut ONE brochure

PDF DatasheetTechnical data

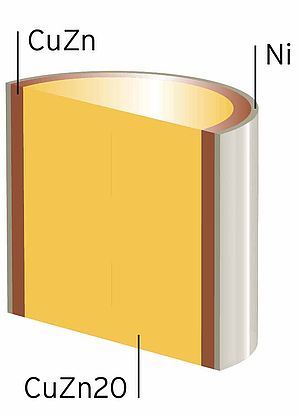

| Core material | CuZn20 |

| Coating | Ni (pure sheath technology) |

| Surface | Paraffin-free |

| Tensile strength | 800 MPa / 116,000 PSI |

| Elongation | > 1% |

| Color | grey-gold |

Cross-section

Delivery program

Run-off-times wire electrodes

Further product information

Berkenhoff GmbH (headquarters)

- Kinzenbach plant

- Berkenhoffstrasse 14

- 35452 Heuchelheim

- Germany

- +49 641 601 0

- +49 641 601 222

- info(at)bedra.com

Berkenhoff GmbH

- Merkenbach plant

- Rehmühle 1

- 35745 Herborn

- Germany

- +49 2772 5002 0

- +49 2772 5002 155

- info(at)bedra.com